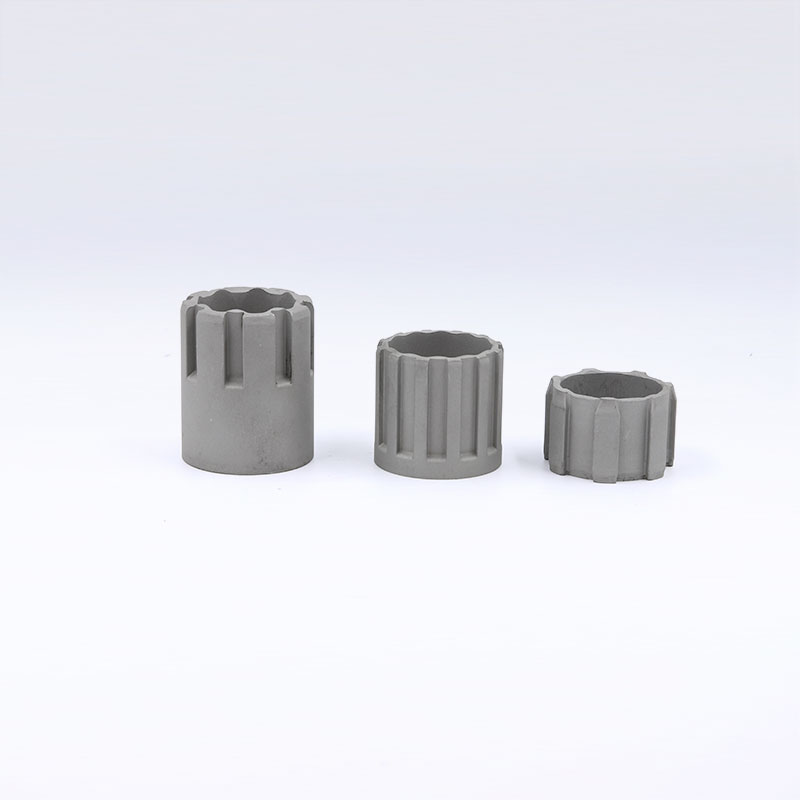

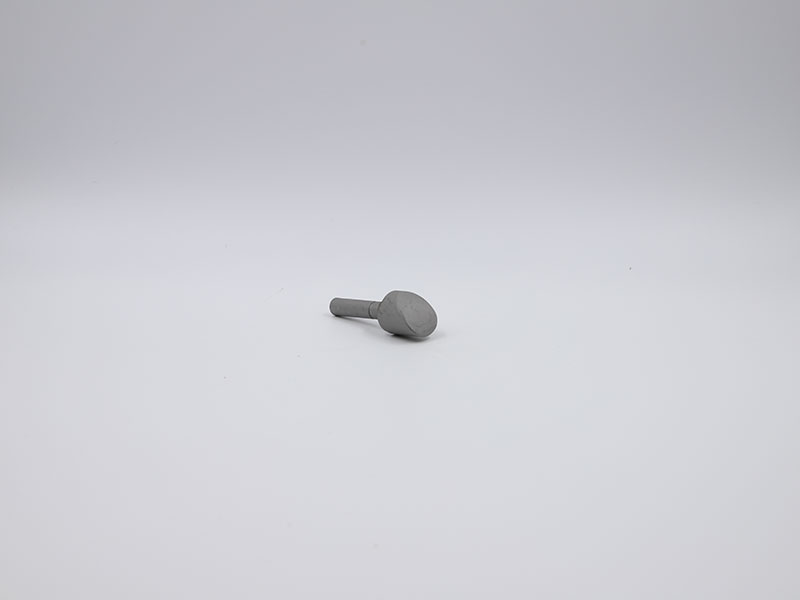

Highly complex cold forged components

We produce highly complex parts using the cold forging technique. Thanks to the collaboration with certified partners for the raw materials and the minimum necessary subsequent treatments, we guarantee a high-quality and optimized production for large quantities.

Specialized mainly in the automotive sector, we are also opening ouselves up to other sectors thanks to our internal mechanical processing department.

Co-design and analysis

Optimized production

Machining and heat treatments

Checks and packing

Steel and aluminum for highly complex components

In addition to the production of steel components, we constantly invest in research and development to test and verify which could be the best aluminum alloys in terms of lightening, resistance to corrosion, mechanical characteristics, but also in terms of improvement of deformability due to an ever lesser use of the material during its use.

Thanks to cold forging, we produce complex components with external and internal teeth, with length up to 280 mm and with high strain ratios

Saving raw materials

With cold forging, up to 70% of material (steel, aluminum, copper) is saved compared to machining process, also reducing the carbon footprint of the product.

Maximum mechanical properties

Following the hardening due to cold deformation, the mechanical properties of the material are maximized.

Less production costs

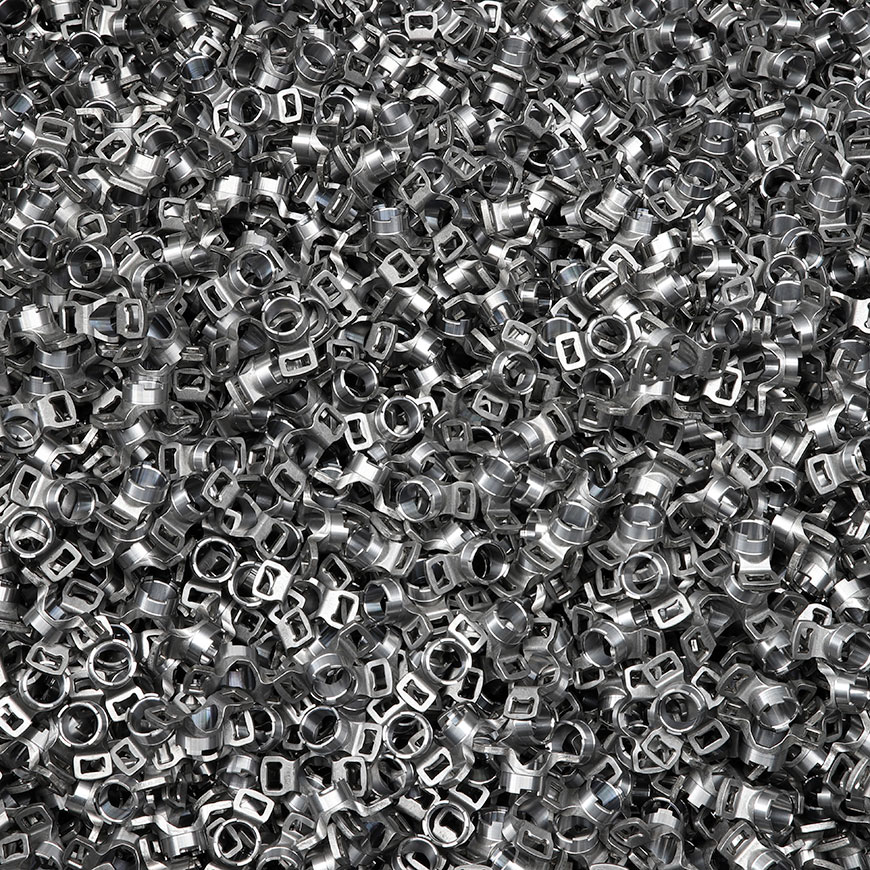

In addition to saving raw materials, we reduce production costs thanks to high productivity: up to 80 pieces per second.

Minimal subsequent work

The possibility of achieving an almost finished shape of the required piece by deformation minimizes any secondary mechanical processes.

Stable and repeatable cycle

We guarantee a stable, repeatable and convenient production cycle for high production volumes.

Highest quality finish

Thanks to our experience, we guarantee an optimal general quality and surface finish.

Precision components for automotive and industry

Given the great commitment required by this technology for the design and construction of moulds, we have always turned mainly to the automotive sector.

Now, thanks also to the additional skills acquired in the field of turning, we bring our know-how in the production of complex components to other sectors as well.

Let's forge a new partnership

Do you want to make your project a reality?